🏗️ Sieve Analysis Test for Fine Aggregate

🔍 Purpose

The Sieve Analysis Test for fine aggregate is conducted to determine the particle size distribution of sand. It helps classify the sand as fine, medium, or coarse and assess its suitability for concrete or mortar production. Proper gradation ensures workability, strength, and durability in construction.

📘 Reference Standard

- IS 2386 (Part 1):1963 – Methods of Test for Aggregates for Concrete: Part 1 Particle Size and Shape

- ASTM C136 / C136M – Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates

⚙️ Apparatus Required

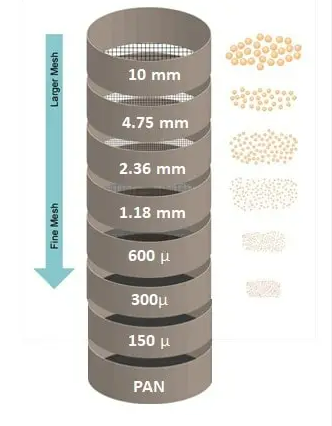

- Set of IS sieves: 4.75 mm, 2.36 mm, 1.18 mm, 600 µm, 300 µm, 150 µm, and pan

- Weighing balance (accuracy ±0.1 g)

- Sieve shaker (mechanical or manual)

- Brush for cleaning sieves

- Oven (for drying samples at 105°C – 110°C)

🧪 Sample Preparation

- Obtain a representative sample of fine aggregate (about 500 g).

- Dry the sample in an oven at 105°C – 110°C until constant weight is achieved.

- Allow the sample to cool to room temperature before sieving.

🧰 Procedure

- Arrange the sieves in descending order of size — 4.75 mm at top and 150 µm at bottom, with a pan below.

- Weigh the dried sample (W1).

- Place the sample on the top sieve and shake it for 10–15 minutes using a mechanical sieve shaker.

- After sieving, weigh the material retained on each sieve (Wr).

- Calculate the percentage retained and the cumulative percentage retained on each sieve.

📐 Calculations

Percentage retained on each sieve = (Weight retained / Total weight) × 100

Cumulative % retained = Sum of % retained up to that sieve

% Passing = 100 − Cumulative % retained

📊 Example Table

| IS Sieve (mm) | Weight Retained (g) | % Retained | Cumulative % Retained | % Passing |

|---|---|---|---|---|

| 4.75 | 10 | 2 | 2 | 98 |

| 2.36 | 40 | 8 | 10 | 90 |

| 1.18 | 80 | 16 | 26 | 74 |

| 0.60 | 150 | 30 | 56 | 44 |

| 0.30 | 160 | 32 | 88 | 12 |

| 0.15 | 60 | 12 | 100 | 0 |

🧮 Fineness Modulus (FM)

Fineness Modulus = (Sum of cumulative % retained on standard sieves) / 100

Example:

FM = (2 + 10 + 26 + 56 + 88 + 100) / 100 = 2.82

✅ Result: The Fineness Modulus of sand = 2.82 (Medium Sand)

📏 Grading Zone of Fine Aggregate (as per IS 383:2016)

| Sieve Size (mm) | Zone I (%) | Zone II (%) | Zone III (%) | Zone IV (%) |

|---|---|---|---|---|

| 4.75 | 90–100 | 90–100 | 90–100 | 95–100 |

| 2.36 | 60–95 | 75–100 | 85–100 | 95–100 |

| 1.18 | 30–70 | 55–90 | 75–100 | 90–100 |

| 0.60 | 15–34 | 35–59 | 60–79 | 80–100 |

| 0.30 | 5–20 | 8–30 | 12–40 | 15–50 |

| 0.15 | 0–10 | 0–10 | 0–10 | 0–15 |

📋 Importance

- Ensures uniformity and consistency in sand quality.

- Helps determine the concrete mix proportions.

- Prevents segregation and improves workability.

- Controls water-cement ratio and strength of concrete.

⚠️ Precautions

- Clean and dry sieves before and after use.

- Do not overload sieves with excess sample.

- Shake sieves for adequate and uniform duration.

- Use oven-dried sand for accurate results.

📘 Conclusion

The Sieve Analysis Test helps classify sand according to particle size distribution. Fine aggregates with a fineness modulus between 2.3 and 3.2 are suitable for most concrete works. Properly graded sand improves strength, reduces voids, and enhances durability of concrete structures.